Radiographic testing (RT) - NDT Inspection Labs & RT Enclosure

NABL ISO 17025 Accredited RT Testing Labs at Bangalore, India

Trinity NDT Labs at Peenya Industrial Area, Bangalore, Karnataka, India are NABL ISO17025 accredited - Radiography testing including Gamma Ray Radiography Inspection using Iridium 192 sources and X-ray Radiography testing, Ultrasonic Testing, Magnetic Particle Testing, Penetrant testing and Eddy Current Inspection Methods.

Download NABL Accreditation certificate of Trinity NDT or Quick Contact Us.

India’s Fastest Growing NDT Company

Trinity NDT is India’s fastest growing NDT & Welding Inspection Services Company equipped with General NDT & Aerospace NDT Labs at Bangalore, India.

World Class NDT Testing Labs - Radiography X-ray Testing Facilities

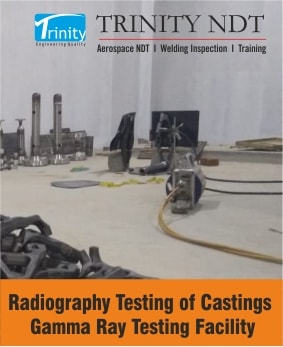

State of Art in-house Radiography Enclosure facility to carryout inspections that meets international standard and to deliver RT test results in quickest time frame. The Radiography enclosure RT testing facility is approved by Atomic Energy Regulatory Board AERB, BARC, Department of Atomic Energy, Government of India, Mumbai, India. The RT testing Labs are approved for both Gamma Ray Radiography testing and X-ray Radiography testing of Castings, Weld joints and other engineering components for Industrial Applications.

The Gamma Radiography, X ray labs are also approved by Center for Military Airworthiness (CEMILAC)" - A defense organization under the Ministry of Defense, Government of India for Nondestructive testing NDT of aerospace components / Airborne Systems for Indian Military Applications.

Radiography Enclosure Facility at Bangalore Karnataka India

A unique NDT Lab of its kind for Industrial Radiography in India and is catering to the needs of Radiography testing of Casting, Weld joints and assembled components and structures. NDT labs are facilitated with 5T EOT crane facility for carrying heavy castings and fabricated structures inside Radiography enclosure.

A modern Radiography film processing Dark room is attached to the Labs for Processing the Films on time. Reference Radiographs ASTM E446 and other Casting, Welding Radiography Reference standards are available for Film Interpretation and Evaluation.

Safety in Radiography

Trinity NDT Labs are NABL Accredited ISO17025 certified and Radiography Testing RT labs are safety ensured to meet the requirements of AERB. The RT testing Labs are under the close supervision of Radiological Safety Officer – RSO & Site Incharge to ensure safety round the clock and BARC Certified Industrial Radiographers Level I will carry Radiography exposures. The Certified Radiographers at Trinity NDT have right blend of theory and practical exposure mended by in-house NDT RT Level III to handle critical RT testing applications with greater efficiency.

A team of RT Interpretation professionals leaded by ASNT NDT Level III in Radiography Testing to provide effective means of Interpreting tough jobs with high level of accuracy. Frequent training sessions on Radiation safety are organized internally to keep the Radiographers and professionals updated on Radiations Safety. Know more about the Team at Trinity NDT.

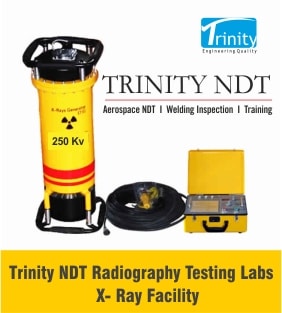

Radiography Testing – Radiation RT Sources & Infrastructure

- Gamma Ray Radiography by Iridium Ir-192 Source – Roli 2 & Roli 3 IGREDs

- X-Ray Radiography Equipment –250Kv

- RT Enclosure for Ir-192 – Up to 100 Curie

- Radiation Survey Meters

- Radiation Dosimeters

- Safety Accessories – CV Tongs, Lead Pots, Lead Balls, Lead Sheets

Industries, Companies & Locations served by Trinity NDT in India

RT of Castings and RT of Welds, Pipe lines, pressure vessels, Heat exchangers, Boiler components, precision components, cross country pipe line construction, Helipad structures, Petroleum Refinery Tanks, and other engineering industries.

Providing reliable NDT inspection services fine tuned to the client needs. Our core competence includes experienced team of NDT Level I, II, III certified professionals on RT, state of art equipments & approved testing procedures that meets national and international standards. We can perform inspection both in-house and onsite at your site or works. We are serving Pan India including industrial hubs in Bangalore, Chennai, Mumbai, Kochi, Hyderabad, Visakhapatnam-Vizag, Vijayawada, Ranchi, Gurgaon, Noida, Jaipur, Kolkata, Delhi-NCR, Coimbatore, Pune, Nagpur, Patna, Jamshedpur, Ahmedabad, Mangalore, Bhilai-Raipur, Bhubaneswar-Odisha and Hosur Tamilnadu.

Contact us

Key Features of RT Testing Facilities

- Iridium 192 gamma ray and X-ray inspection equipments that meets international standards

- Modern testing equipments perfectly equipped for high sensitivity applications

- Dark room for film processing and Film Interpretation facilities

- Radiography inspection personnel are qualified and certified to BARC RT Level I, II certified, RT Level I, II certified as per written practice framed to the requirements of recommended practice SNT-TC-1A and or IS:13805 certified by Indian Society for Nondestructive testing (ISNT) and are approved by leading third party inspection authorities

- Experienced in house NDT Level III consultants and experts for providing techniques establishment, procedure preparation, approval and consultancy services.

- NDT Level III trainers for conducting in house or external NDT Level 1, 2 training and certification courses on Radiography testing and other NDT inspection methods. Read more about Radiography Testing Personnel Certifications.

- Strong team of NDT Level 2 certified professionals to provide Radiography or X-ray testing services across India

Training and Certification on Radiography Testing, Film Interpretation Trinity Institute of NDT Technology (A Training Division of Trinity NDT Engineers) offers World class training & Certification courses on Radiography Testing and Radiography Film Interpretation Courses.Know more about Training & Certifications offered with us."

Basics and Principles of RT, X-Ray Testing

Radiography is one of the most widely used and time proven NDT Method to test engineering components to find internal flaws in Castings, Weld Joints and Structures. The method is much suitable for finding volumetric discontinuities and also used for assembled components.

RT is based on differential absorption of penetrating radiation- either electromagnetic radiation of very short wave-lengths (Gamma Rays) or particulate radiation (Alpha & Beta Rays) by the part or test piece being tested. Because of differences in material density and variations in thickness of the part, or differences in absorption characteristics caused by variation in composition, different portions of a test piece absorb different amounts of penetrating radiation. Unabsorbed radiation intensity passing through the part can be recorded on film or photosensitive paper, viewed on a florescent screen or monitored by various types of electronic radiation detectors to identify flaws and other anomalies.

The term radiography testing usually implies a radiographic process that produces a permanent image on film or digital form. Although in a broad sense it refers to all forms of radiographic testing, Neutron radiography refers to radiographic testing using a stream of neutrons rather than electromagnetic radiation unlike Gamma Rays & X-Rays.

Industrial Radiography – Uses & Applications

Industrial Radiography inspection is used to detect features of a component or assembly that exhibit a difference in thickness or physical density as compared to surrounding material. Large differences are more easily detected than small ones. In general, radiography can detect only those features that have an appreciable thickness in direction parallel to the radiation beam. This means that the ability of the process to detect planar discontinuities such as cracks depends on proper orientation of the test piece during testing. Discontinuities such as voids and inclusions, which have measurable thickness in all directions, can be detected as long as they are not too small in relation to section thickness. In general, features that exhibit a 2% or more difference in absorption compared to the surrounding material can be detected. Radiography is more effective when the flaws are not planar.

Applicability

Industrial Radiographic testing is used extensively on castings and weldments. Radiography is also well suited for testing of semiconductor devices for cracks, broken wires, unsoldered connections, foreign material and misplaced components. Sensitivity of radiography to various types of flaws depends on many factors, including type of material, type of flaw and product form. Both ferrous alloys can be radiographed, as well as non-metallic materials and composites.

Advantages of Radiography

- RT Technique is not limited by material type or density.

- Can inspect assembled components.

- Minimum surface preparation required.

- Sensitive to changes in thickness, corrosion, voids, cracks, and material density changes.

- Detects both surface and subsurface defects.

- Provides a permanent record of the inspection such as Films.

Disadvantages of Radiography

- Many safety precautions for the use of high intensity radiation.

- Many hours of technician training prior to use.

- Access to both sides of sample required.

- Orientation of equipment and flaw can be critical.

- Determining flaw depth is impossible without additional angled exposures.

- Expensive initial equipment cost.