Ultrasonic Inspection Testing (UT) ISO17025 NABL Accredited NDT Labs at Bangalore India

Ultrasonic Testing or Ultrasonic Inspection as conventionally called as UT testing is one of the most widely used Nondestructive testing NDT method to find internal flaws using Ultrasonic waves to inspect Ingots, Castings, forgings, rolled plates, sheets, bars, rods, weld joints, shafts, gears, and other engineering components in cast, forged, machined condition, during manufacturing and in-service inspections. Ultrasonic thickness testing is also used for measuring remaining wall thickness using Ultrasonic principle.

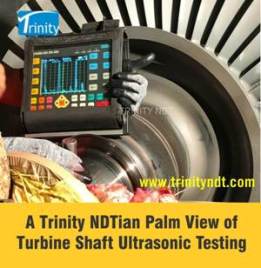

Ultrasonic Inspection facility in India at Trinity NDT labs, Bengaluru

Trinity NDT– Ultrasonic testing Labs are equipped with advanced Ultrasonic Equipments for in lab and onsite NDT Inspections by our certified NDT UT Level II professionals. In house ASNT NDT Level III experts will closely monitor every Ultrasonic inspection activity to meet customer specifications and compliance to international codes, standards and client UT procedures.

UT Inspection Capabilities

Contact, straight beam, angle beam, dual beam techniques, immersion testing of thin materials for Aerospace application, special probes for Ultrasonic Inspection of Weld joints, Equipments with DAC, DGS and TCG facility for flaw size evaluation, specialized Ultrasonic equipment for inspection of Aerospace composite structures. Every Ultrasonic equipment, probe and reference block is perfectly calibrated as per standard operating procedures.

NABL ISO17025 Accredited NDT Company

Our NDT labs at Peenya Industrial Estate, Bengaluru, India are NABL ISO17025 Accredited for Ultrasonic testing, Magnetic Particle inspection, Penetrant testing, FPI testing, Radiography testing and Eddy Current testing. To know more about our NABL accreditation and scope of testing download NABL accreditation certificate of Trinity NDT at Downloads page of this website.

Aerospace NDT Labs at Bengaluru India

Trinity NDT labs are specially equipped to carry Ultrasonic inspection of composite materials and metallic structures for Aerospace NDT applications. FPI testing , Eddy Current testing , MPI testing, Ultrasonic testing, Radiography X-ray facilities meets aerospace standard requirements.

Codes, Standards & Specifications on UT

Ultrasonic inspections are carried out as per approved NDT procedures and specifications such as ASTM E 114 – Straight Beam Ultrasonic testing, ASTM A 388 – UT of Heavy steel forgings. ASTM A 609 – UT of Castings, ASTM E 435 – Ultrasonic testing of plates using straight beam examination, ASTM A 577 – UT testing of plates for special applications, ASTM A 578 – Angle beam Ultrasonic testing of steel plates, American Welding Society AWS Structural Welding codes Acceptance Criteria for Ultrasonic testing - AWS 1.1, 1.3, National Aerospace Laboratories Specifications NDTS and other national and International Standards.

Most of the ultrasonic inspection instruments detect flaws by monitoring one or more of the following:

Ultrasonic thickness Gauging Test Facility

Ultrasonic thickness gauging is one of the effective tools to control wall thickness of pipes, tubes and other components during manufacturing and in-service inspection of boiler pipes, tubes, plates, castings, oil and gas pipe lines and other components to check wall thickness loss due to corrosion erosion and other loss mechanisms. Our NDT labs equipped with digital Ultrasonic thickness gauges and high temperature Ultrasonic probes for high temperature applications. Specially formulated couplants are available for LOX compatible applications and high temperature ultrasonic inspections.

Ultrasonic Inspection Applications

Ultrasonic testing or inspection (UT) is used for quality control and materials testing in all major industries. This includes Ultrasonic testing of castings, forgings, plates, extruded components, weld joints, electrical and electronic component manufacturing, production of steel, aluminum and titanium, fabrication of structures such as air frames, pressure vessels, ships, bridges, motor vehicles, machinery and jet engines. In service ultrasonic testing for preventive maintenance is used for detecting impending failure of rail road rolling stock axles, press columns, earth-moving equipment, mill rolls, mining equipment and other machines and components. The flaws to be detected include voids, cracks, inclusions, pipe, laminations, bursts and flakes. They may be inherent in the raw materials, may result from fabrication and heat treatment, or may occur in service from fatigue, corrosion or other causes. Ultrasonic testing can also be used to measure thickness of metal sections during manufacturing and maintenance inspections.

Ultrasonic testing Limitations

Ultrasonic testing Limitations

- Manual Ultrasonic Flaw detection requires careful attention by experienced technicians to carryout testing and evaluate inspection results

- Extensive technical knowledge is required for the development of Ultrasonic testing procedures. Download Sample Ultrasonic inspection procedure

- Parts that are rough, irregular in shape, very small or thin or non-homogenous materials are difficult to be tested using ultrasonic principle

- Discontinuities that are preset in a shallow layer immediately beneath the surface may not be detectable for which Surface NDT methods such as Liquid penetrant testing, Magnetic particle testing, Eddy current testing are recommended.

- Couplants are needed to provide effective transfer of ultrasonic wave energy between Ultrasonic probes and components being tested.

- Ultrasonic Reference standards are needed, both for calibrating the equipment and for characterizing flaws.

Ultrasonic Inspection facilities at Trinity NDT, Bangalore, India

- NABL ISO17025 Accredited NDT labs for Ultrasonic testing and other NDT tests

- State of the Art Ultrasonic flaw detection equipments with built-in DGS curves, AVG, AWS flaw sizing techniques for weld inspections

- Transducers suitable for critical inspections, most sensitive, high temperature and highly attenuative materials inspection applications

- Experienced in house ASNT NDT Level III consultants and experts for providing techniques establishment, procedure preparation, approval and consultancy services

- ASNT NDT Level III trainers for conducting in house or external NDT Level 1, 2 training and certification courses on Ultrasonic testing and other NDT inspection methods. Read more about Ultrasonic Testing Personnel Certifications.

- Ultrasonic inspection professionals qualified and certified to Level I, II as per ASNT recommended practice SNT-TC-1A and IS:13805 by Indian Society for Nondestructive testing (ISNT) and are approved by leading third party inspection authorities.

- Strong team of NDT professionals to provide ultrasonic inspection services across India

Most of the ultrasonic testing equipment detects flaws by monitoring one or more of the following:

- Reflection of energy from metal-gas interfaces, metal-liquid interfaces or discontinuities within the metal itself due to impedance mismatch

- Time of energy from metal-gas interfaces, metal-liquid interfaces or discontinuities within the metal itself due to impedance mismatchof transit of a Ultrasonic sound wave through the test piece from the entrance point at the sending (transmitting) transducer to the exit point at the receiving transducer, and

- Attenuation of the beam of sound waves by absorption and scattering within the test piece.

We at ‘Trinity NDT’ provide reliable inspection services on Ultrasonic testing fine tuned to the client needs. Our core competence includes experienced team of NDT Level II, III certified professionals on UT, state of art equipments & approved testing procedures that meets national and international standards. We can perform inspection both in-house and onsite at your site or works. We are serving Pan India including industrial hubs in Bangalore, Chennai, Mumbai, Kochi, Hyderabad, Visakhapatnam-Vizag, Vijayawada, Ranchi, Gurgaon, Noida, Jaipur, Kolkata, Delhi-NCR, Coimbatore, Pune, Nagpur, Patna, Jamshedpur, Ahmedabad, Mangalore, Bhilai-Raipur, Bhubaneswar-Odisha and Hosur Tamilnadu.

Apart from India participants from following countries have been certified at Trinity NDT in Bangalore India. Australia, Azerbaijan, Russia, US, UK, Norway, Dubai, Thailand, Malaysia, Singapore, Papua New guinea, Sri Lanka, Nigeria, South Africa, Kenya, UAE, Saudi Arabia, Oman, Kuwait, Tanzania, Yemen, Ethiopia, Qatar, Philippines, Maldives, Sudan, Bangladesh, Pakistan, Afghanistan, Bhutan, Nepal, Iran, Iraq, Syria, Libya, Cameroon, Angola, Congo, Portugal, Uganda, Mozambique.

Want to learn more about ut & Nondestructive testing ? We would like to share our experience and expertise through NDT & Welding Inspection training certification courses. Join us at our NDT certification course offered by Trinity Institute of NDT Technology, Bangalore, India as per ASNT SNT TC 1A for your Level I & II certification on Ultrasonic testing UT Level I/II. Trinity NDT can also train and certify QA/QC personnel on Eddy Current inspection, Magnetic particle testing, Liquid penetrant testing, Radiography testing, Radiography film interpretation, Visual testing and Ultrasonic thickness gauging. Contact us for more information on courses eligibility, fee structure and training schedules Contact us.